ID card laminates significantly enhance the durability and lifespan of printed cards by providing a protective layer that shields against physical wear, moisture, UV exposure, and tampering. This added layer helps prevent fading, scratching, and smudging of printed data, especially in high-use environments like government agencies, healthcare facilities, and corporate settings.

helps prevent fading, scratching, and smudging of printed data, especially in high-use environments like government agencies, healthcare facilities, and corporate settings.

Laminates also improve the card’s resistance to chemical damage and extend its structural integrity, reducing the need for frequent reissuance. For secure ID programs, custom holographic laminates add an additional layer of visual security, deterring counterfeiting and unauthorized duplication.

Why are hologram laminates so expensive?

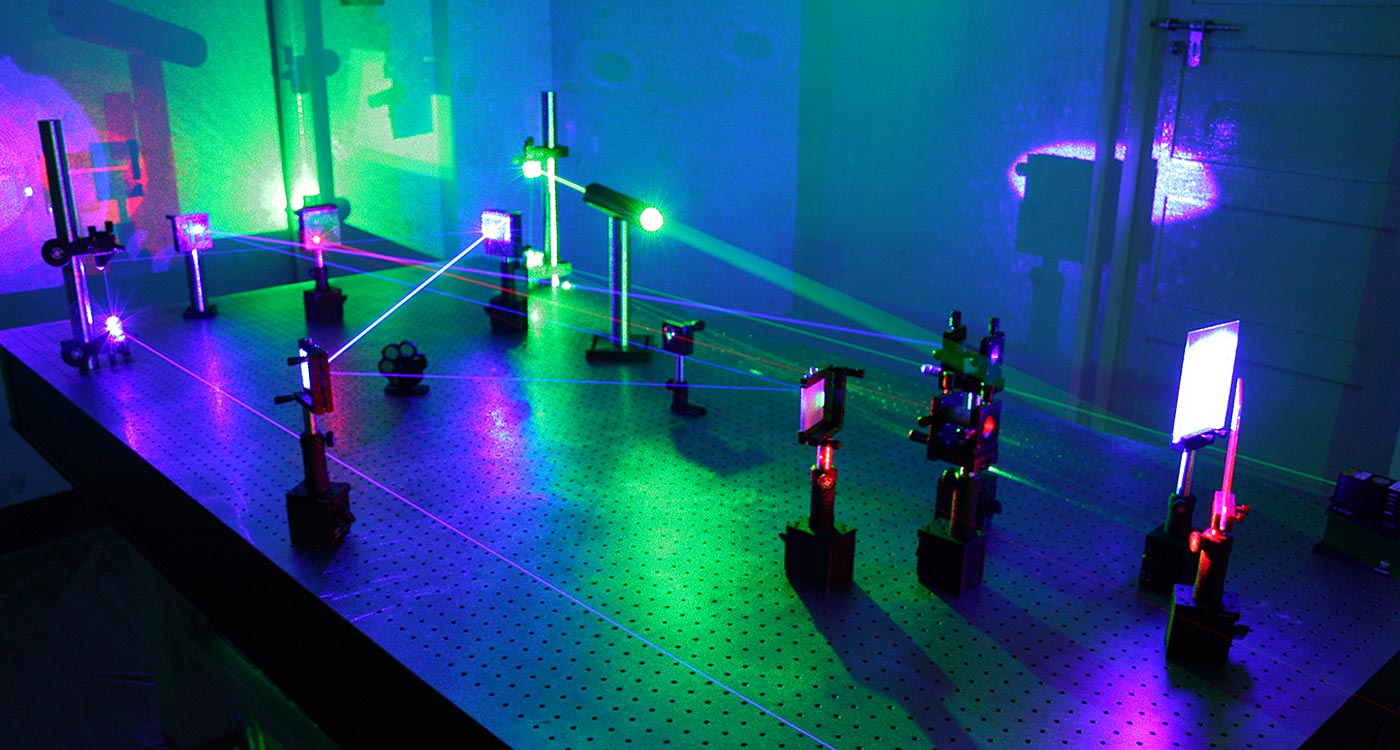

The theory of holography was first introduced in 1947 by Dennis Gabor, but it wasn’t until the invention of the laser in 1960 that holography became practically feasible. Early holograms were created using complex optical setups in laboratory environments. In later decades, especially from the 1980s onward, the development of dot-matrix holography revolutionized the field by enabling high-resolution, computer-controlled production of holograms for security applications such as ID cards and banknotes. These systems work like precision laser “printers” and offer far greater efficiency than the original optical methods. However, once the holographic master is created, the more complex steps of replication, embossing, and integration into secure materials begin.

Key steps for hologram integration:

- Hologram origination and creation of master

- Electroplating master hologram for duplication

- Step-and-repeat of hologram to create web-width master

- Electroplating to create production embossing cylinders

- Embossing of hologram images onto web-width treated polyester film

- Vacuum-metallization to vaporize zinc to apply to film to create a bright and durable image

- Multiple coating steps to add adhesives and other coatings to optimize the film for ID Card printer application

- Converting web-width treated and embossed film to meet printer registration mark and size criteria

- Finishing individual rolls with labels and packaging

What’s the turnaround time?

IDP maintains a selection of stock “generic” holograms that are not tied to any specific customer and are readily available. For details on current inventory, please contact us or your sales rep.

If you’re interested in developing a custom, brand-specific custom hologram, please consider the following:

- The typical lead time from final artwork approval to delivery is up to 10 weeks.

- A minimum order of hologram laminates is required—enough to produce at least 10,000 cards.

- When stored under ideal conditions, the shelf life of the laminate is approximately two years.

Final thoughts:

- Data shows that laminating your cards significantly extends their lifespan by improving durability and reducing fading. In fact, a laminated card can last up to three times longer than an unlaminated one. Adding a generic hologram laminate increases the cost per card by only about 30%, making it a cost-effective way to enhance both durability and security.

- For high-security environments, creating a custom, organization-specific hologram offers the same protective benefits while greatly enhancing card security through unique visual authentication.

Contact Us to Learn More!